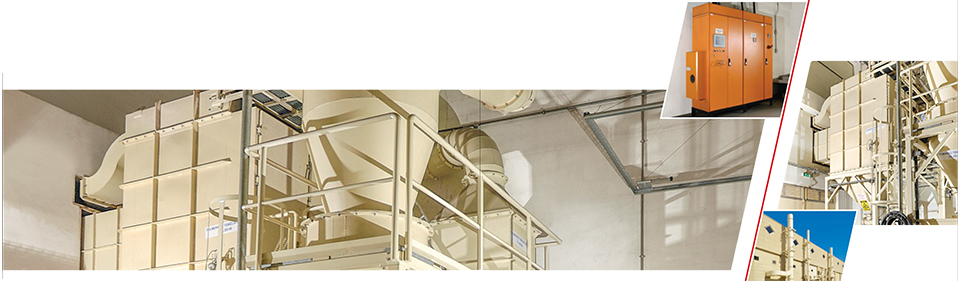

Sigara üretim sahasının genel temizlik ihtiyaçlarını karşılamak üzere tüm alana yayılmış 60 farklı noktadan istenilen sabit bir vakum değeri ile çalışan ekipman ve borulama sistemi projesinin tasarımı ve uygulanması gerçekleştirilmiştir.

Yeni kurulan Fabrika üretim sahası içerisinde muhtelif noktalardan istenilen sabit bir değer ile emiş yapabilecek merkezi bir vakum ve toz toplama sistemi tasarımı istenmiştir.

Her emiş noktasında 200m³ saat debi ve 1000 daPa vakum basıncı, çalışma dinamiklerine bağlı kalmaksızın enerji verimliliğini de ön planda tutan otomasyon sistemi aracılığıyla programlanarak, sahanın merkezi vakum sistemi ile temizlenmesi sağlanmıştır.

Projelendirme aşamasında, üretim sahasında kömür tozunun da bulunmasından dolayı sisteme patlama kapakları, yangın algılama ve söndürme ekipmanları dahil edilmiştir.